Radround Infrared Heaters

Glenro’s Radround infrared heaters and systems are the perfect solution for wire, cable, fiber optic, tubing, and extruded profile processing operations that require intense, precisely controlled heat. With Radround heaters, the product is surrounded by heat, allowing for efficient and uniform heat transfer. This minimizes oven dwell times and ensures that you can speed up your process lines without sacrificing product quality.

The Radround heater’s quartz cylinder is heated by a resistive metal heating element, emitting radiant energy as it gets hot. Product passing through the center of the heater receives uniform energy around its entire circumference, and the remaining heat is reabsorbed by the quartz cylinder, reducing the amount of electric power required to maintain operating temperatures. With their high watt density, Radround heaters are ideal for applications that require a lot of energy input in a small space.

The quartz cylinder of the Radround heater is tough enough to withstand impacts from most products that might strike or rub against it, and its high temperature operation results in waste product coating materials burning away cleanly, requiring little if any heater maintenance. Closed loop automatic feedback control systems keep Radround heaters at a constant temperature for consistent processing and product quality.

Glenro offers three models of Radround heaters, each suited to different types of manufacturing applications. Radround heaters are 42” long with interior diameters ranging from 2” to 14”, and are available in a variety of watt densities. Our infrared systems include the heaters, temperature controls, supporting steel framework, material handling systems, air input and exhaust. We ship the systems assembled, tested and ready to install. Ovens can be configured vertically or horizontally depending on your application.

At Glenro, we understand that every manufacturing process is unique, which is why we can help you select the best infrared source for your application. Our technical support team is always available to answer any questions and help you optimize your process for maximum efficiency and productivity.

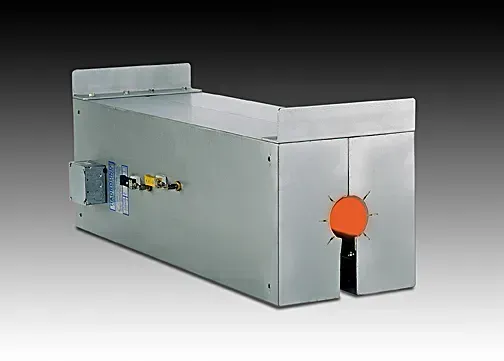

Radround Series 40

This basic Radround model uses a solid quartz tube to heat the product passing through its center, uniformly and efficiently.

Radround Series 41

For processes that require spindle conveyors or manual threading, you can specify Keyhole Radround heaters. These heaters include a slot to allow access for the conveyor, as well as easier product threading.

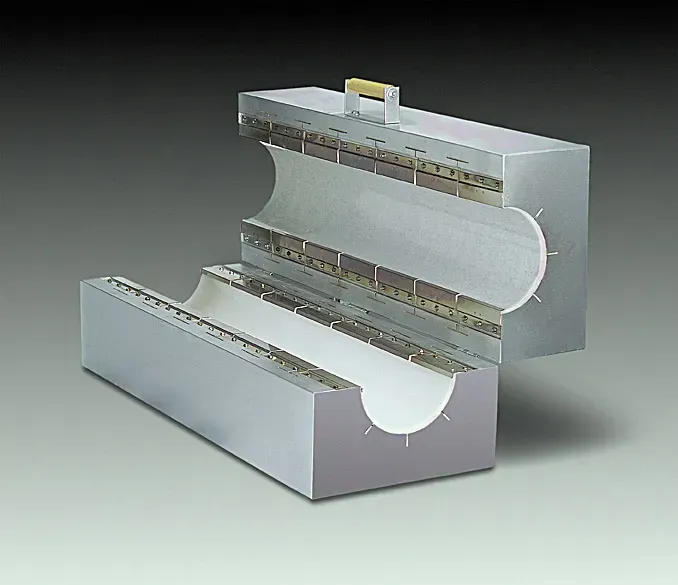

Radround Series 42

If you need quick, easy access to your product for threading or removal, split Radround heaters are the answer. These heaters deliver the same intense, efficient heat as the Solid Round model, but they use a split quartz cylinder and a hinged case for easy opening. Glenro can add optional lift handles or air driven lifting mechanisms for easy opening.