Industrial Infrared Solutions

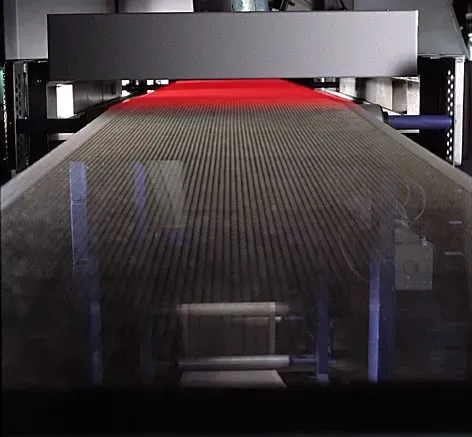

Advanced Infrared Heating Systems for Industrial Applications

Custom-Engineered Infrared Solutions Designed for Precision, Efficiency & Reliability

For over 65 years, Glenro has delivered advanced infrared heating systems that empower manufacturers to achieve precise thermal processing, optimized energy use, and consistent, high-quality production. Our cutting-edge infrared technologies—ranging from heaters and ovens to air systems—are engineered to meet the diverse needs of global industries.

Our Infrared Solutions

At Glenro, we offer a comprehensive suite of infrared heating systems tailored to your production requirements:

Radplane Infrared Heaters

- Uniform, high-intensity heat transfer for rapid and consistent processing.

- Energy-efficient design that reduces operational costs.

- Compact and easily integrated into existing production lines.

Radplane Quartz Lamp Heaters

- Instant heat-up and cool-down for enhanced process efficiency.

- Precise wavelength control to match varied material needs.

- Ideal for automotive, aerospace, textiles, and printing applications.

Radround Infrared Heaters

- 360° even heating for round or irregularly shaped components.

- Customizable configurations for optimal performance in pipe, tubing, or cylindrical processing.

Infrared Ovens

- Integrated with convection or forced air to boost drying and curing speeds.

- Designed for precise temperature control while reducing energy consumption.

Infrared Air Systems

- Combine infrared radiation with forced convection to accelerate moisture removal.

- Enhance product quality and minimize defects in drying, curing, and coating processes.

Why Choose Glenro Infrared Systems?

We don’t just supply equipment—we engineer success. Our infrared systems are built on a foundation of industry-proven expertise and innovative design:

Precision Temperature Control

Advanced zoning and closed-loop feedback deliver uniform heat distribution.

Rapid Process Integration

Fast start-up and cool-down times boost production efficiency and minimize downtime.

Energy Efficiency

Our systems are optimized to reduce energy consumption, cutting operational costs.

Seamless Integration

Custom-engineered to fit seamlessly into new or existing production lines with minimal disruption.

Our Process: From Concept to Completion

Process Testing & Feasibility Analysis

Validate your process with pilot testing and feasibility studies.

Ongoing Support & Optimization

Enjoy continuous improvements, equipment upgrades, and dedicated service support.

Ready to Transform Your Thermal Processing?

Discover how Glenro’s advanced infrared heating systems can optimize your production process. Contact us today to schedule a consultation and learn more about our custom-engineered solutions.