Radplane Series Infrared Heaters

Glenro’s Radplane infrared heaters are the perfect solution for predrying, drying, curing, preheating, and heating applications that require intense, precise heat. With a broad band of medium and long wavelengths, these high-efficiency heaters emit energy that is easily absorbed by most products. The heating elements are mounted on high-temperature insulation backings and radiate directly at the product for efficient heating. Unlike ceramic, quartz, or glass-faced heaters, Radplane heaters don’t inhibit the radiant energy or retain heat on shutdown.

Thanks to their Rapid Response technology, these heaters can reach operating temperature in seconds on startup, preventing delays. On line stops, the elements lose heat so rapidly that residual heat won’t damage your product. Radplane heaters offer a high conversion efficiency of electrical power input to usable radiant energy, saving power costs. As electricity deregulation and pricing policies continue to change, electric infrared heat is becoming more cost-effective than ever.

With closed loop feedback controls, the temperature is precisely controlled to give you consistently high-quality product. The element spacing and ability to form edge and center zones ensure uniform product heating. Radplane heaters deliver up to 4800 watts per square foot at temperatures up to 1500°F, making them perfect for heating products in tight spaces. These heaters are available in many sizes and can be configured to heat even the widest products uniformly. Input voltages range from 115 through 575. The heating elements can be mounted in machine direction, across machine direction, or skewed. We use corrugated ribbon foil, expanded metal, or sinuated wire elements, depending on the electrical configuration and energy requirements of your application.

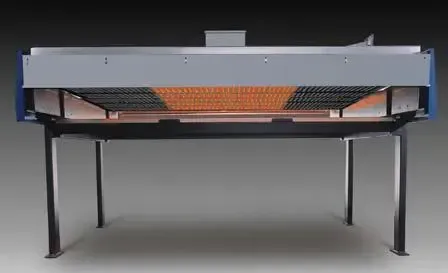

Radplane Series 80

The versatile series 80 serves a variety of heat processing applications for webs, fabrics, sheets, parts and particles. You can get the heaters by themselves, with temperature controllers and SCR power controllers, or as part of custom designed oven systems.

Radplane Series 81

The Radplane Series 81 heating elements run in machine direction and can be configured with edge and center zones that operate at different temperatures. The photos show edge zones turned on and off to accommodate webs and fabrics of different widths. For other applications, edge zones can operate at higher temperatures to compensate for edge losses. Series 81 also has a patented construction that maintains uniform heating across wide products when multiple heaters are installed side-by-side. In addition, we can skew the elements to provide even heat across the product so you won’t have problems with cold spots or streaking.

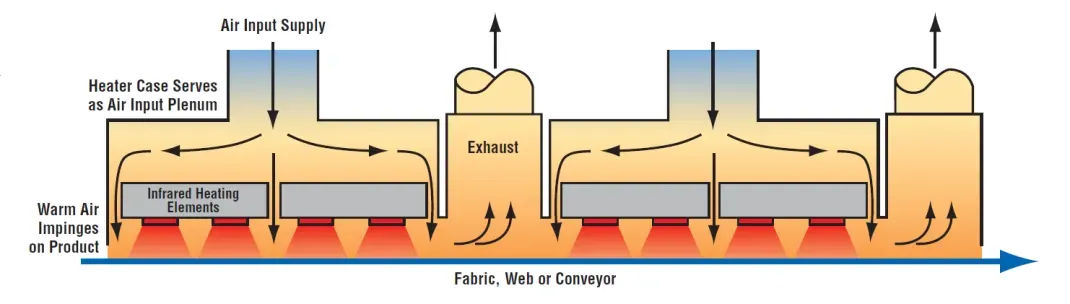

Radplane Series 82/85

The Radplane Series 82/85 has air input to accelerate drying and to help remove evaporated water or solvent. Air is introduced to the product through uniform slot nozzles formed between heater modules. This integrated heater design provides clean airflow and uniform energy across the width of the product.

Radplane Ceramic Face Electric Infrared Heaters — Series 36, 37, 38, and 39

Glenro Radplane ceramic face infrared heaters emit a consistent heat pattern from edge to edge. The heat is so uniform and so closely controlled that you can mount a Radplane ceramic face heater just inches from the surface of your product for excellent energy transfer efficiency. Large area-source ceramic face heaters are self-cleaning, and require little maintenance. That’s true no matter what vapors your manufacturing process may emit. They’re ideal for a wide range of manufacturing applications including drying, curing, sintering and many others. You can use Radplane ceramic face heaters in close-packed configuration for manufacturing processes that require uniform product heating. Different temperature control zones within the heater array let you fine-tune your process with precision. Radplane ceramic face heaters are available in widths of 6” or 12”, in lengths to 6’. Choose wattages from 500 to 2000 watts per square foot in voltages ranging from 115 to 575.